What types of led light strip manufacturers are classified by process

The growth of the LED light strip market space has stabilized. On the other hand, due to the low threshold of LED light strips, many small medium-sized enterprises have entered the field. This has led to increasingly fierce market competition, profits have been repeatedly compressed. In the face of this environment, many leds Light strip manufacturers began to shift their focus, even completely abandon the LED light strip business, turned to other fields. Just as Mr. Qian Zhongshu described in "The Besieged City", "People in the city want to go out, people outside the city want to come in", the current LED light strip field is truly performing this scene. To this end, the newspaper specially adopted the special planning of "LED lights with" siege ": Some people want to go out, some people want to come in, the special planning for you to interpret the current development status trends of the LED lamp belt industry.

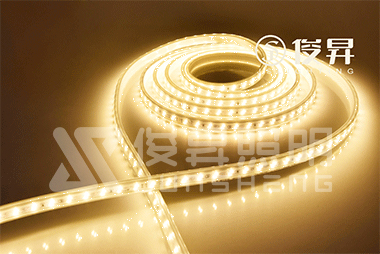

1.led light strip manufacturers are classified according to process: LED in-line light strip LED patch light strip. Conventional LED in-line light strips include LED neon lights, LED rainbow tubes, round two lines, round three lines, flat three lines, flat four lines, flat five lines, etc .; conventional LED patch light strips include soft light strips, hard light strips, colors are Red, green, blue, yellow, white, colorful, etc.

2.Classified by waterproof grade; waterproof LED light strip non-waterproof LED light strip

3. Classified by voltage: high voltage LED strip low voltage LED strip

4. Classification by lamp beads: 3528 light strip, 5050 light strip, 3014 light strip, etc.

LED lamp strip refers to the LED lamp beads are soldered on copper wire ribbon flexible circuit board (FPC) using special processing technology, soldered on rigid circuit board (PCB), then connected to a power source to emit light, because when it is illuminated The shape is named after a strip of light. In the early stage of LED in-line strips, the process was to weld the LED in-line beads to copper wires. The LED strip manufacturers then put PVC tubes directly molded them with equipment. There are two types: round flat. The number of copper wires is distinguished the shape of the light strip. The two wires are called second wires. A circle is preceded by a circle, that is, a circle second wire; a flat shape is preceded by a flat word, that is, a flat second wire.