Low-voltage light strip is assembled by FPC

Flexible led low-voltage light strips are assembled with FPC as circuit boards assembled with SMD LEDs, so that the thickness of the product is only the thickness of a coin does take up space; there are 18 LEDs, 30 LEDs, 50 cm in length across the specification 15 LEDs, 24 LEDs, 30 LEDs, etc. There are also 60cm, 80cm, etc., different users have different specifications. can be cut at will, can be extended deliberately without affecting the light.

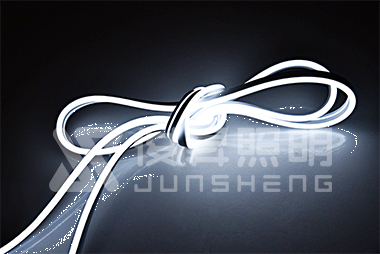

The FPC material is soft can be bent, folded, rolled intentionally. It can be moved retracted in three dimensions without breaking. It is suitable for irregular local small space applications, because it can be bent rolled intentionally, it is suitable for combining various patterns in the advertisement decoration.

When welding led low-voltage light strips, please be sure to use a 30W tip electric soldering iron that does leak electricity. You can first solder one pin of the led engineering light strip to investigate the orientation of the led engineering light strip. After the orientation is correct, solder another pin. Welding should be determined, the welding time should be too long, it should be controlled within 2 seconds, otherwise the led engineering light belt may be welded! We have specially provided an extra led engineering light belt, which is to prevent beginners accidental damage Can be replaced.

The national policy should promote the promotion of led low-voltage light strips, the roadmap is very clear clear to implement as planned. It is to hope that "energy-consuming" incandescent lighting will give way to led engineering light strips, also take out all road lighting parts of cities. As an "experimental" shooting range for LED lighting applications, you believe it now. I believe that the world of LEDs is vast the prospects are optimistic happy. Therefore, LED lamps that are "energy-saving" are constantly pouring into neglecting to be "light"!